- Bruce Thomas Heritage Victoria & Heritage Council of Victoria

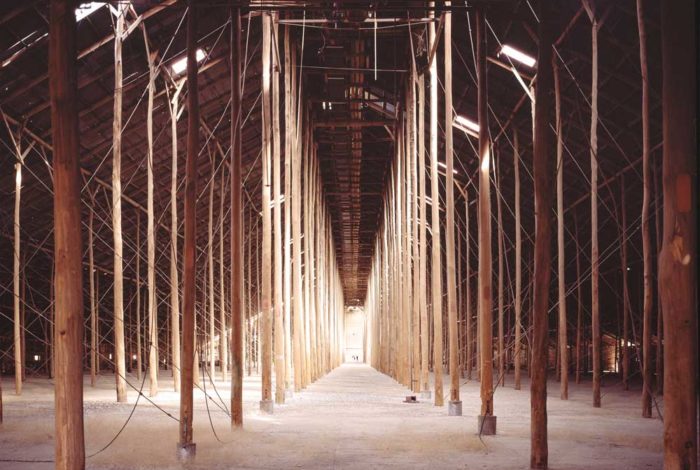

4. How The Stick Shed Functioned

The Stick Shed incorporated filling and emptying systems and had its own dedicated external steam engine to drive it all.

It was located on the main Adelaide to Melbourne railway line. To service these storage sheds, a new railway siding called “Marmalake” was built in 1941 and operated as a staff locked loop siding. An independent connection between Murtoa and Marmalake was provided in December 1950. This allowed shunting to occur without interruption by main line trains. In this era, grain was mostly transported by rail, either in bulk or in sewn jute bags of 3 bushels capacity (180lb each in weight).

Bulk deliveries of grain by train were distributed through The Stick Shed via an elevator and a central conveyor running high along the centre of the shed. Braced internal timber bulkheads on either side of the shed took the lateral thrust of the wheat and a conveyor at ground level outside the south bulkhead took wheat back to the elevator for transport elsewhere by rail again.

Wheat was transferred using a system of “drags” to move the wheat out of the main pile lengthwise and onto mobile conveyor belts that moved it laterally to the fixed south side conveyor.

By 1947, an additional hopper at the East end allowed local deliveries of wheat in bags or in bulk, which connected by an elevator to the filling conveyer.

Over the years systems and machinery were upgraded, for example the initial steam power plant was replaced by diesel motors and then electricity.

The elevator tower is still used today but only for out loading grain.